Efficient inventory solutions for e-commerce are essential for business enterprises due to rapid growth, shorter product lifecycles, and higher customer expectations for order fulfillment. Automated storage systems with smart logistics capabilities, along with high flexibility in supply chain technology, are vital to ensuring the success of today’s fulfillment service businesses.

Comprehensive inventory management contributes to smooth, coordinated and synchronized warehousing and fulfillment processes for handling incoming goods and returned items, not to mention optimal order picking and shipping operations. Hänel has decades of experience and proven know-how when it comes to automated systems that support modern order fulfillment centers.

Above all, e-commerce warehousing must be efficient logistically, reducing the time between when the order is received by the consumer and delivered from the retailer to a minimum. A streamlined order fulfillment process can be achieved through precise coordination of all interrelated processes.

Customers continue to demand deliveries to arrive within ever shorter time schedules, such as same-day delivery, or at predefined dates and times. Innovative warehouse management solutions help businesses narrow the gap between reducing costs and focusing on the customer as they strive to be better than the competition.

There are many approaches to e-commerce warehousing and fulfillment, such as the presorting of customer orders in Click & Collect concepts. Drop shipping and a strategic returns and recycling concept can also be successfully realized with intelligent e-logistics.

Automated storage solutions integrated as strategic elements of the supply chain can considerably boost efficiency and productivity. These solutions support the ideal coordination and synchronization of fulfillment as well as e-fulfillment. They usually consist of:

This technology allows fulfillment companies to combine all kinds of warehouse storage and management systems and thus create holistic solutions for logistics with no need to outsource:

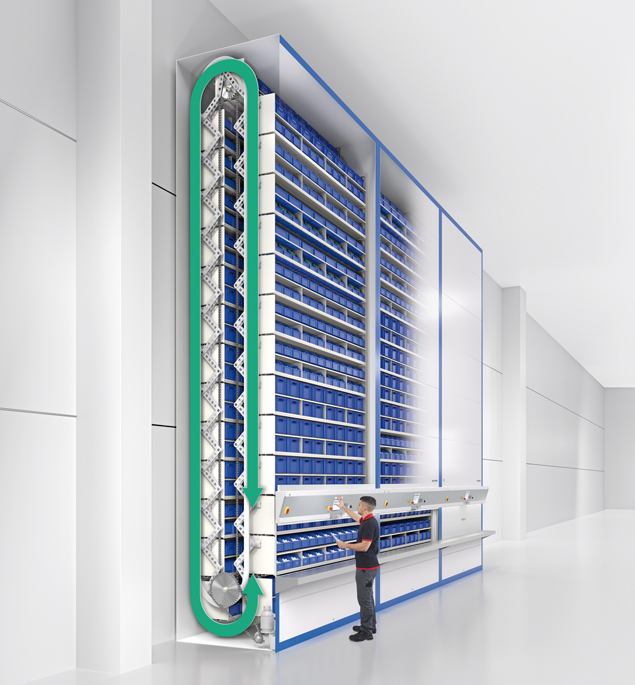

Hänel offers high-tech solutions such as the Lean-Lift® and Rotomat® systems for intelligent storage that satisfies all of the requirements for modern intralogistics and fulfilment. Warehouse organization and fulfillment service go hand in hand. Much like a high-bay solution, the Hänel vertical carousel and the Hänel vertical lift fully utilize the height available in a warehouse. The Hänel Lean-Lift® and Rotomat® systems are the leading solutions in today's marketplace, offering up to 60% more storage capacity than a miniload system having the same footprint. Maximum storage volume within a minimal footprint is possible, as well as access to all items from a single retrieval point.

Our trade fair schedule is in the planning stage.

Details about our participation in future trade fairs will be available here soon.

A warehouse management system (WMS), which is based on very efficient omni-channel logistics, is an IT application that enables accelerated order processing. The WMS ensures sustainable customer service and is a decisive competitive factor in today’s marketplace, especially in the B2B sector. Logistics processes for inventory management and warehousing must be centrally orchestrated and coordinated; upstream and downstream processes such as confirmation of payment transactions and the transfer of shipments to delivery services must also be included. All of this is possible by consolidating various software applications in one centralized WMS. Hänel storage systems enjoy seamlessly integrations with customer systems using Hänel controllers equipped with a SOAP web service interface.

This is possible thanks to a web-based and middleware-free link between the Hänel controller and many kinds of ERP solutions – for example, SAP. The interaction of proven hardware, intelligent operating concepts and perfect integration in the customer’s IT offers quite a number of benefits:

•Maximum standardization of labeling and packaging processes, not to mention systems for transparent traceability

• Smart site management with short routing within the e-commerce warehouse

• Faster early stages of the picking process through clever site organization

• Leveraged potential of one’s own picking methods and e-commerce storage

• Automated calculation of optimal picking sequences is possible based on flexible variables such as urgency or transport routes

• Usage of the pick-by-light system to support picking minimizes errors and enables equal and consistent task assignments among employees for more overall productivity in e-commerce storage

• Customized and modern solutions for online shops – Click & Collect, Buy Online, Pick-Up in Store or Drop Shipping – which keep the sales and logistics processes separated

Warehouse management systems coordinate ecommerce order fulfillment, including all put and pick processes. With the right logistics, downtimes and losses resulting from a lack of material can be dramatically reduced.

The program gathers and analyzes various kinds of data for e-commerce logistics – for example, storage position, article master data, storage costs, shelf life, batch numbers, price lists, serial numbers, customer and delivery data, pick lists, goods received and goods shipped.

The Hänel Lean-Lift® is distinguished by the intelligent combination of rationalization and protection of stored items. At the heart of the closed-loop system concept is the IT-driven extractor, which – in combination with the Hänel profile wall – makes height-optimized storage on the Hänel multifunction containers possible. The extractor automatically finds specific storage positions within the system and brings the requisite containers to the access point, which is ergonomically designed to make item retrieval less strenuous. High speed, reliability, space-saving integration, environmentally-friendly manufacturing processes and clear user guidance are additional characteristics of the Hänel Lean-Lift®. With this system you will reduce costs and improve picking performance thanks to faster inventory access. Hänel controllers are delivered ex-works with integrated warehouse management systems. Special options can be added in response to specific customer requests or requirements – one example is EcoDrive® technology for smart energy recovery.

The Hänel Rotomat® is known for its innovative design that results in up to 60% more storage area. The sheet-steel construction of the system housing resembles the cellular structures used in the aircraft industry. Twin three-phase motors ensure smooth yet powerful performance when bringing items stored on system carriers to the access point.

The sliding carriage principle behind the carrier suspension of the Rotomat® makes for smooth and reliable system operation with minimum wear and tear. If system faults should occur, the Rotomat® can still be operated until the service engineer arrives thanks to the Safety Bypass System.